“Clean technology manufacturing” in sheet metal prioritizes minimizing environmental impact by integrating advanced fabrication techniques and sustainable materials. This approach reduces waste and energy consumption while leveraging recycled resources. Key aspects include:

1. Advanced Manufacturing Techniques:

Hydroforming: Shapes complex parts using water pressure, potentially reducing waste and energy in specific applications.

Additive Manufacturing (3D Printing): Minimizes waste by depositing only necessary material for metal components.

2. Waste Reduction:

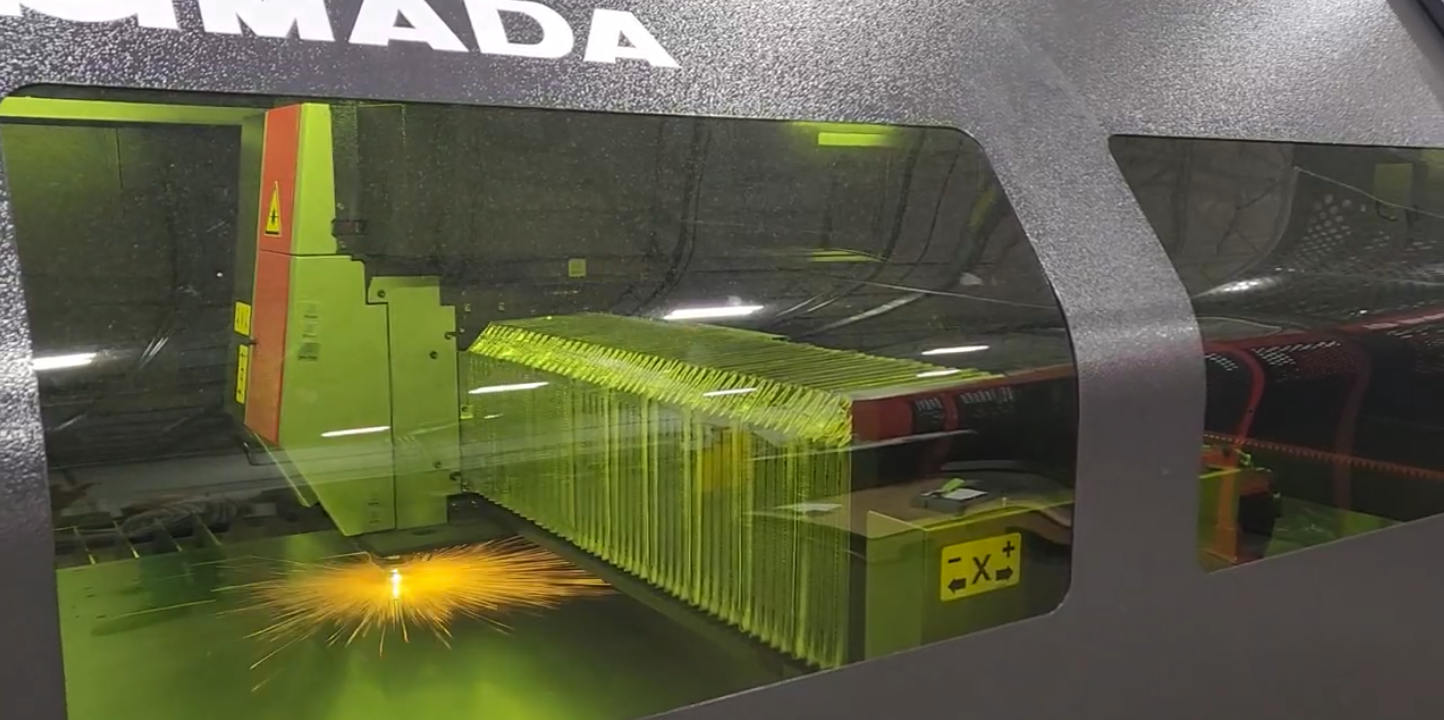

Precision Laser Cutting: Minimizes material waste through highly accurate cuts, outperforming traditional methods.

Optimized Nesting: Software-driven layouts maximize material usage by efficiently arranging parts on sheet metal.

Scrap Metal Recycling: Reintegrates scrap from the manufacturing process into new components, creating a closed-loop system.

3. Energy Efficiency:

High-Efficiency CNC Machines: Reduces power consumption through advanced energy-saving features.

Optimized Tooling: Designs that minimize friction and energy expenditure during forming operations.

4. Sustainable Material Selection:

Recycled Metals: Utilizes recycled aluminum, stainless steel, and other metals, decreasing reliance on virgin materials.

Lightweight Alloys: Employs materials like aluminum to reduce overall weight and material usage.

By strategically implementing these sustainable metal production strategies, the industry can significantly reduce its environmental footprint, conserve valuable resources, and contribute to a more circular and resilient economy. This unified approach, encompassing material sourcing, energy efficiency, waste reduction, and product design, is crucial for ensuring the long-term viability and responsible growth of the metal sector.

Chinese

Chinese