The manufacturing process typically involves several stages, transforming a customer’s concept into a physical product. Careful planning is essential to ensure projects run smoothly from start to finish.

The Larsen Manufacturing Process

Design Review

Upon receiving customer designs, Larsen conducts a thorough design review to understand all specifications and requirements.

Quoting

A detailed quote is then prepared, taking into account material costs and the number of operations required to produce the product.

Design Part 2

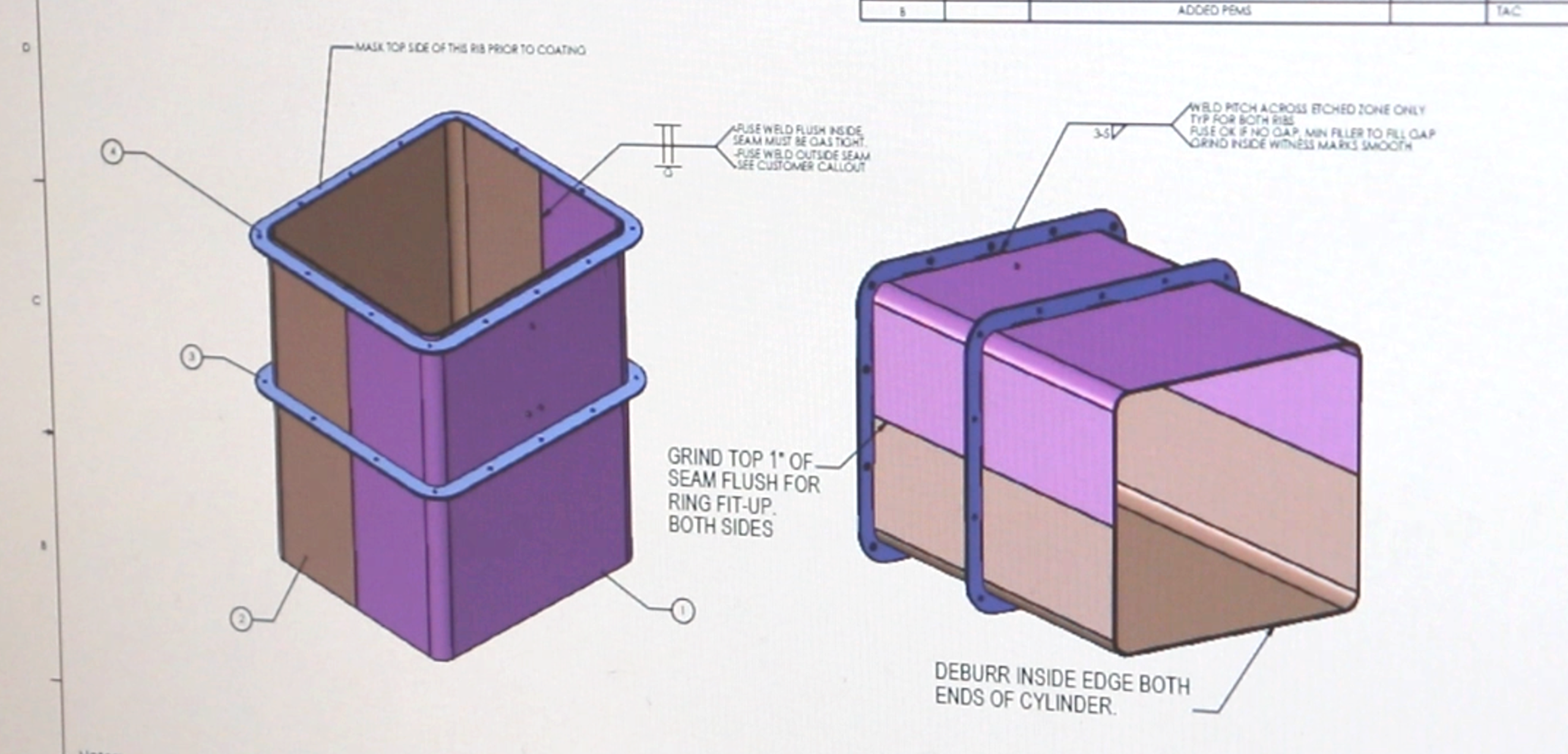

Larsen’s engineers create their own CAD designs for necessary tools and/or to define process parameters, ensuring optimal manufacturing.

Build

For fabricated parts, a prototype is made for inspection and approval before full production begins. For stamped pieces, the next step involves creating a specific die.

Secondary Processes

Fabrication often includes various secondary operations such as forming, spot welding, hardware insertion, and powder coating, adding value and functionality to the product.

Periodic Inspections

Quality control inspections are performed throughout the entire manufacturing process. This ensures the product consistently meets or exceeds established expectations and standards.

Final Assembly

Final assembly services include sticker placement and the inclusion of instructions. Larsen also creates all product-specific labeling.

Packaging & Shipping

Your product is carefully packaged to ensure its safe arrival. We utilize efficient shipping methods to deliver your order promptly and securely.

At Larsen, we are committed to delivering high-quality products through a meticulously planned and executed manufacturing process. Our multi-stage approach, combined with rigorous quality control, ensures your vision is brought to life with precision and efficiency.

The reference information for this blog was compiled by Larsen’s intern, Camryn Sheehan.

Chinese

Chinese