After safety, quality is the number one priority at Larsen Manufacturing. As an industry leader in quality systems and quality assurance, we develop and execute smart processes consistently.

Deploying Lean, Six Sigma, 8D, and 5S, we are guaranteed to work as efficiently and effectively as possible. Here are some answers to common questions about our implementation process.

What are your quality certifications?

Larsen Manufacturing holds ISO 9001:2015 and IATF 16949:2016 certifications. We are on track to complete ISO 14001:2015 certification by April-May 2025.

When is quality implemented?

Quality Assurance (QA) processes start with the initial customer RFQ request and flow down to all appropriate stages of the NPI and APQP processes, and production implementation.

How is quality incorporated?

Quality Assurance (QA) and Quality Control (QC) processes are incorporated within Larsen Quality Management System via multiple manuals, procedures, work instructions, and more.

How is accuracy maintained?

Larsen QA teams follow a Production Part Approval Process (PPAP) from Level 1 up to Level 5.

During PPAP, multidisciplinary teams are involved in process development and process validation, ensuring the customer specs are fully met.

Are control plans set in stone or can they be customized?

Larsen Manufacturing is a diversified company serving the automotive, aerospace, medical devices, energy & automation, consumer goods industries, and others. That means quality teams are gathering customer requirements from different industries, and ensuring they flow down into Larsen’s control plans, and other QA documentation.

What do your control plans consist of?

Our control plans are based on requirements received from our customers and bolstered by internal expertise of running similar products.

If a customer does not have specific requirements, our standard control plan will be used. QA Engineers will review customer drawings and determine which dimensions and/or features needs to be controlled and monitored during the production process.

What kind of inspection tools do you use?

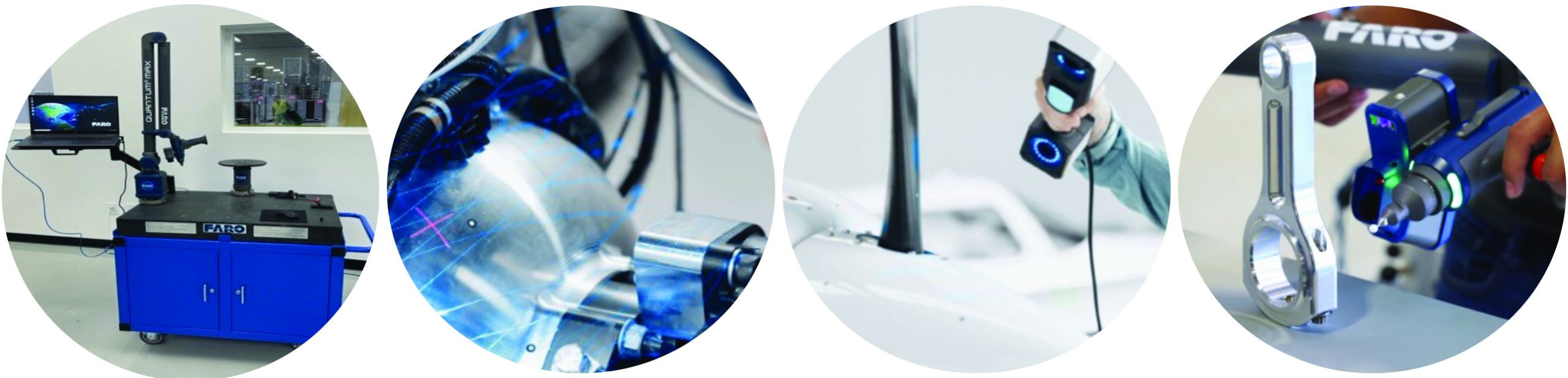

Larsen’s QA Labs are equipped with the most advanced inspection tools, such as CMM’s,

FARO Arms, 2D and 3D Laser Scanners, Optical Comparators and Vision System. Additionally, the QA labs contain standard handheld inspection tools such as height gage, micrometers, calipers, pin gages, thread gages, and more.

Larsen’s culture of ongoing improvement and can-do attitudes has set the organization apart from the competition. The company is committed to providing whatever is needed to meet customer’s quality requirements, from basic dimensional checks to full dimensional layouts, PSWs and PPAPs. Larsen ensures parts consistency, even with tight tolerancing and complex parts.

Chinese

Chinese